Indigenous cuts or Ceylon cut

|

|

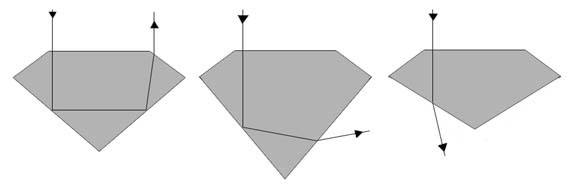

These cuts can be easily recognized due to their often non symmetrical pavilion. What is the advantage for the stone cutter or the gemstone dealer ? This question has been in my head for a while.

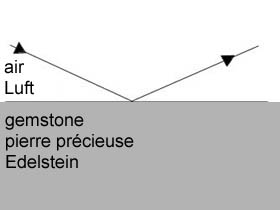

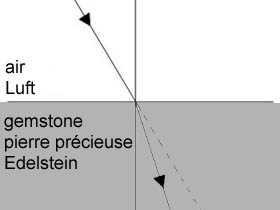

Imagine you are the owner of a parcel of 1 kilo of rough sapphires and you want them to be cut. If you pay the cutter by the hour, he may waste an enormous amount of time to improve his gain. If you pay him by the piece, he may cut as many small stones he can. As the salaries are so low you are forced to survey your cutter permanently to make sure no rough material disappears. As this is a waist of time and not reasonable for commercial stones, you may pay him by the total weight of cut sapphires he delivers back. This is to insure nothing is stolen or cut on purpose into small sizes. The result will be that the cutter cuts as heavy as possible. He will adapt the faceting angles rater to the shape of the rough stone than to consider the optical properties and the light refraction.

Although they are a must to obtain a maximum of brilliance. You may look at it in many ways; a cheap and ideal solution does not exist. The faceted stone reflects the way the stone cutter has been paid and how the trade is organized.

Out of your kilo of sapphires you will receive between 200 or 300 grams of cut stones. The loss due to the cut depends mainly on the shape of the rough stones. Another important factor is the shapes you order. If you for example order only oval shapes, then the cutter has to squeeze also the rough with another shape into this form. This is paired with a higher loss of weight. According to my experience you will have a loss of weight at about 50 - 60% if the rough is in all its dimensions very close to the shape of the cut stone. This is pure chance and rarely the case. Ordinarily the loss is 70 - 80%. It is difficult to control the cutter this way. In addition you have to consider the inclusions. Do you prefer a big stone with many inclusions or rather several small ones with less or without inclusions ? Export restrictions for rough stones in some countries, are designed to help the local gemstone cutting industry. This leads to cheap cuts ordered by some dealers to observe the export rules. Then the stones are sent to foreign factories to be re-cut. This happens at least for the top quality stones.

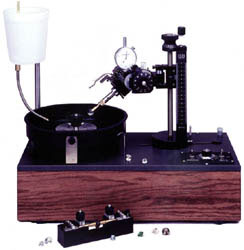

Compare: in Idar-Oberstein Germany a cutter who is specialized to peridot, topaz and synthetic spinel obtains CHF 12.- (US$ 9.-) for a faceted stone between 1 - 2 carats. In India, China, or Sri Lanka you may receive the same work for US$ 1.- per carat. The effort to cut this stone may not exceed 20 minutes. Therefore these cuts are as simple as possible and often cut with the most simple machines, as the JemPeg setup.

The price for stones cut on fully automated machines is higher than US$ 1.- per ct. The precision is better, but the loss of material is much higher. Therefore, mostly synthetic stones are cut on these machines. For example Golay Buchel delivers, depending the industry, fully automated cuts for watch makers and hand cut stones to the jewelry manufacturing industry. With a precision faceting machine I need about 2 hours for a 2-6 ct brilliant cut. Cutting in series will bring this to 1 hour. This is the reason why these old not very precise machines like the JemPeg are still in use. They allow to cut faster, and speed is more important than precision.

At the beginning of my cutting activity, more than 10 years back, I believed that in certain countries the knowledge about optimum cutting angles was not available. Today I know that this is not the case. This knowledge is around. I met very good stone cutters in Mexico who knew perfectly well how to cut a perfect stone. But the price of their work does not correspond to the price of gemstone import or export companies. As a result almost non trained workers are hired and they cut stones mainly to meet the price of the market and to serve the low price industry. Beauty, brilliance or high value will not be gained trough this. The quality work of the masters goes to collectors. Without them the know-how for quality work will slowly be lost. And this will happen also to India, Sri-Lanka and China. I am in the happy position to cut for my pleasure and not to depend on this income. I am not forced to sell at the lowest price. If so I would probably have lost interest in this very satisfying and creative profession. This luxury to accept only decent paid cutting jobs is not offered to everybody. The gemstone trade is strongly influenced by the behavior of the customer. For a fast gain many traders do not care too much about the truth. The price or better the big and fast gain guides the trade. Rules and honorable codices are a badly adapted tool to organize a fair trade, as they are often contradictory to the need of the market. Sample pictures before and after recutting for best brilliance. Hubert Heldner Montreux August 2003 |

Deutsch

Artists

Collection

Education

Mineralshows

Publications

Tools

Contact

Links

Back to Home